Yamaha Apex AEM EFI System

150+ HP, Dyno Proven, Auto Tuning, Knock Sensing, Full Data Logging & Remote Tuning

Starting at

2006-2010 Apex - DISCONTINUED click here for alternative

2011-2018 Apex - DISCONTINUED click here for alternative

Engine NOT included

Experimental Aircraft ONLY, 2006-2010 APEX BASE SYSTEM

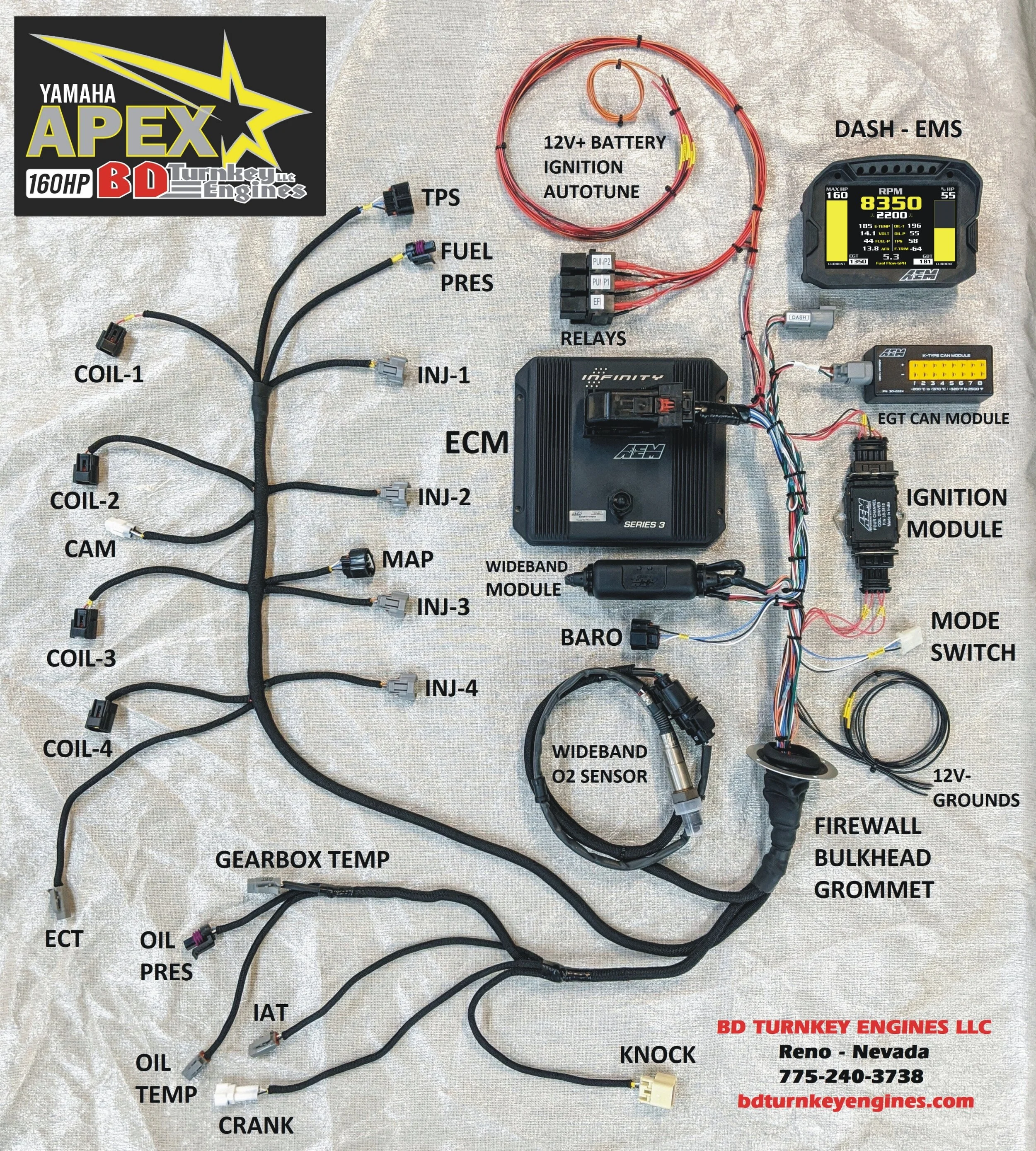

This system is designed for Experimental Aircraft and includes the following:

AEM Series 3 ECM pre loaded with BD Turnkey Engines Naturally Aspirated tune.

NEW Wiring Harness, aviation specific Tefzel wire AND NEW plugs.

Wideband O2 Sensor and “Auto Tune” feature.

Ignition igniter, 4 channel

IAT Temp Sensor, w/ aluminum weld in bung

Knock Sensor, w/ bolt

Coolant Port Plugs & Caps

Complete & Detailed Install Manual w/ pictures, initial setup, start, & troubleshooting procedures.

Base System is to replace the factory Yamaha ECM and Wiring Harness with all new components for an aviation type application but with added features of Knock Sensing / Compensation, “Auto Tune” via Wideband O2 Sensor, IAT Spark compensation, FULL data logging and Tuning. Engine monitoring can be done via laptop but NO Dash / EMS is included in base system. See options below for full plug-n-play “EMS” solutions.

See video link to the RIGHT for dyno tuning numbers. After more than 50 full throttle pulls and countless hours of mid range and idle tuning I averaged 158HP with this system and many pulls well over 160HP. Stock Yamaha EFI made about 145HP - see video! I use the more conservative SAE atmospheric corrections like the big car companies compared to many “internet HP” claims these days still using the older STANDARD corrections.

Experimental Aircraft ONLY, 2011-2018 APEX BASE SYSTEM

This system is designed for Experimental Aircraft and includes the following:

AEM Series 3 ECM pre loaded with BD Turnkey Engines Naturally Aspirated tune.

NEW Wiring Harness, aviation specific Tefzel wire AND NEW plugs.

Wideband O2 Sensor and “Auto Tune” feature.

Ignition igniter, 4 channel

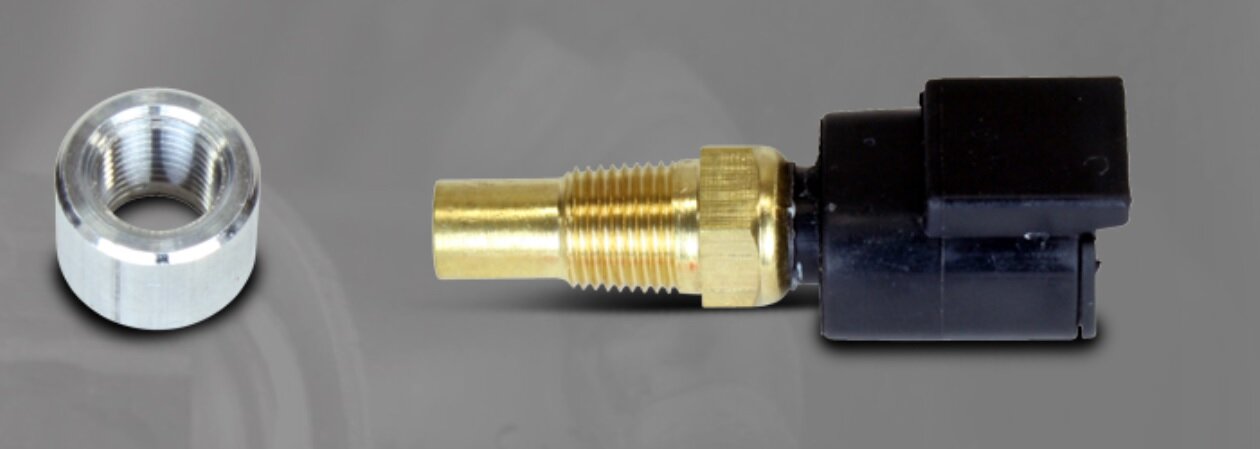

IAT Temp Sensor, w/ aluminum weld in bung

Coolant Port Plugs & Caps

Fuel Filter / Regulator w/ AN adapters

Complete & Detailed Install Manual w/ pictures, initial setup, start, & troubleshooting procedures.

Base System is to replace the factory Yamaha ECM and Wiring Harness with all new components for an aviation type application but with added features of Knock Sensing / Compensation, “Auto Tune” via Wideband O2 Sensor, IAT Spark compensation, FULL data logging and Tuning. The factory IACV is also used for great cold weather starts and smooth & consistent idle. System is supplied with a preset fuel pressure regulator / filter that runs 58psi. Engine monitoring can be done via laptop but NO Dash / EMS is included in base system. See options below for full plug-n-play “EMS” solutions.

See video link to the RIGHT for dyno tuning numbers. This 2011 Apex made no less than 160hp. I use the more conservative SAE atmospheric corrections like the big car companies compared to many “internet HP” claims these days still using the older STANDARD corrections.

Experimental Aircraft Yamaha APEX AEM EFI System Options

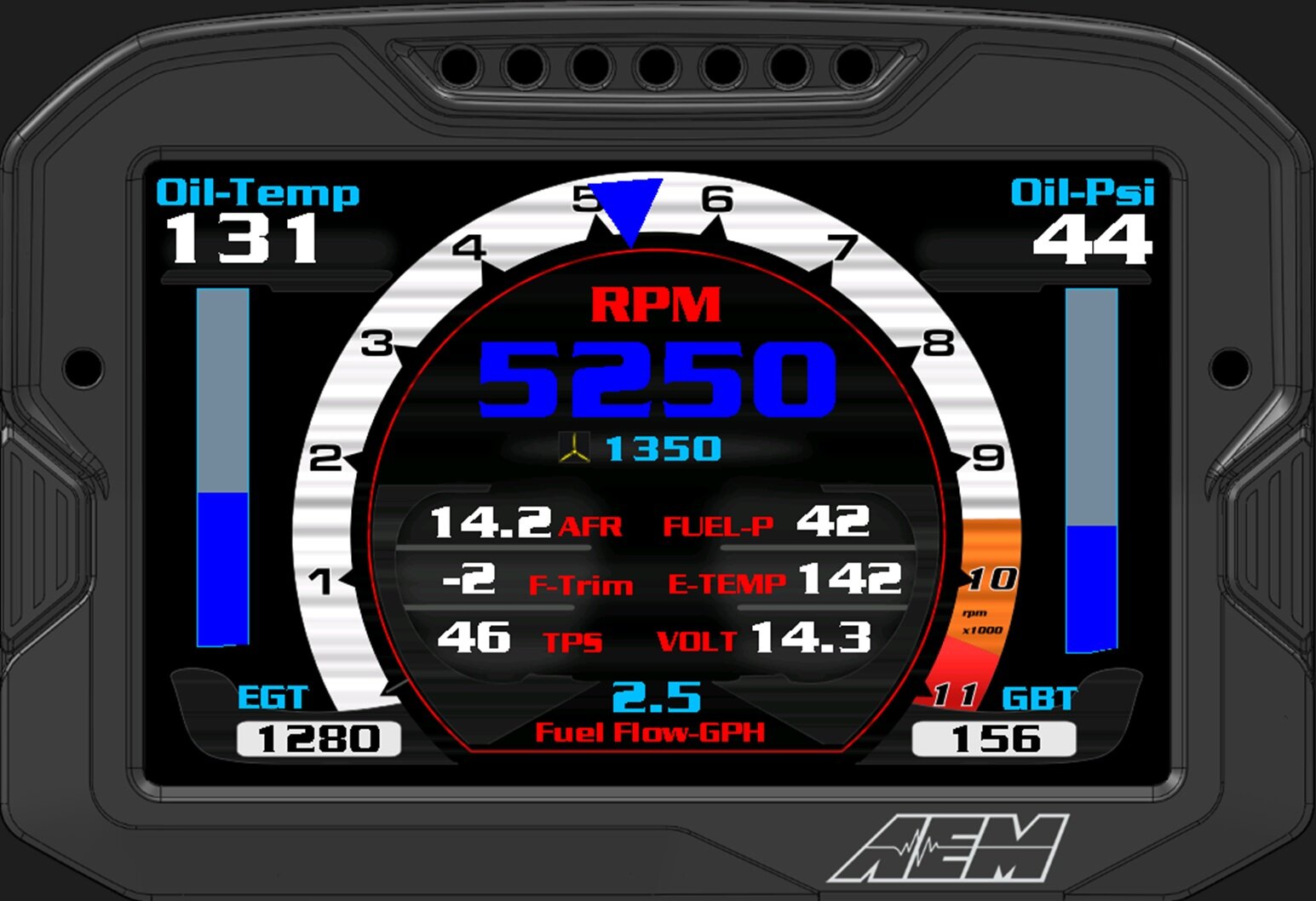

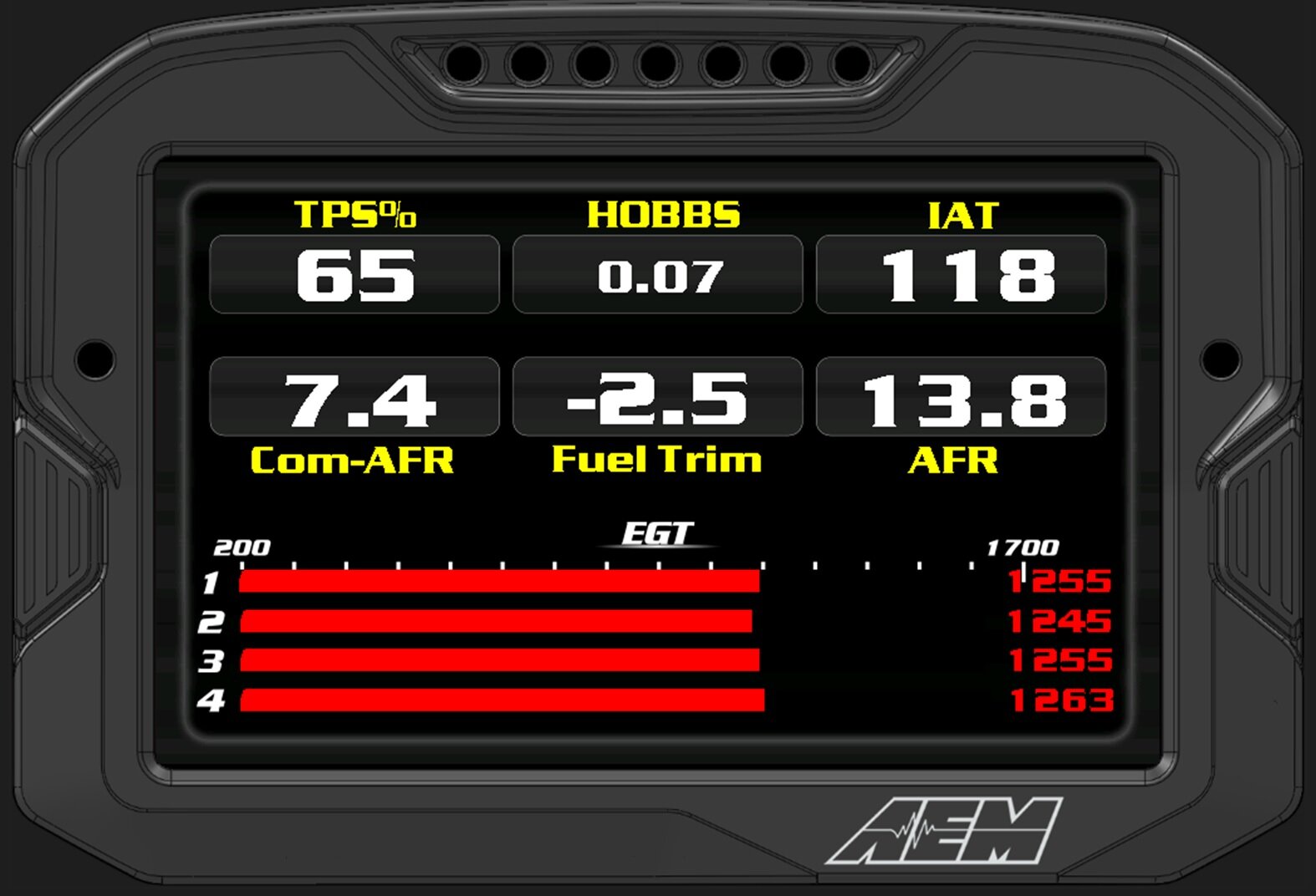

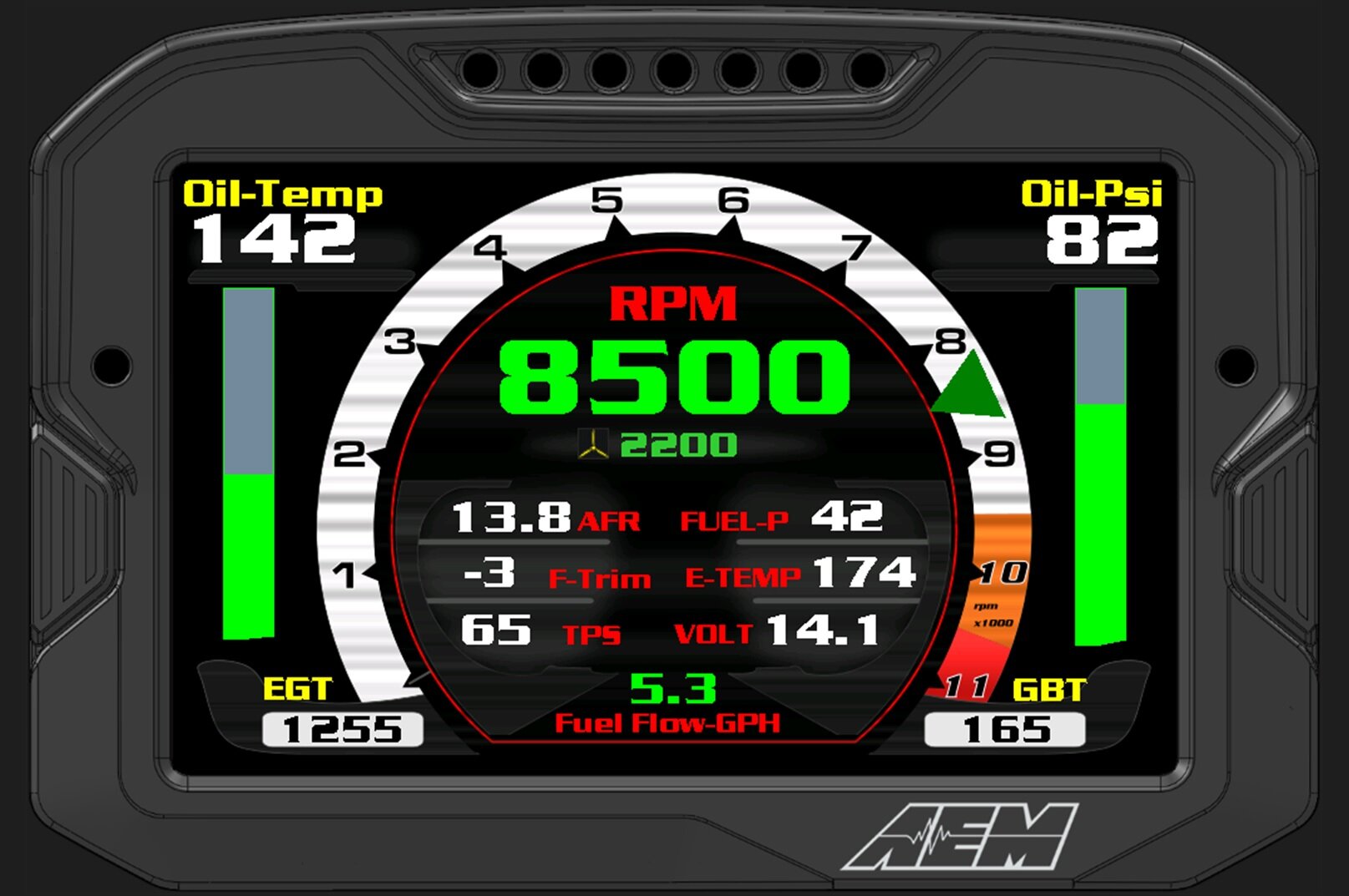

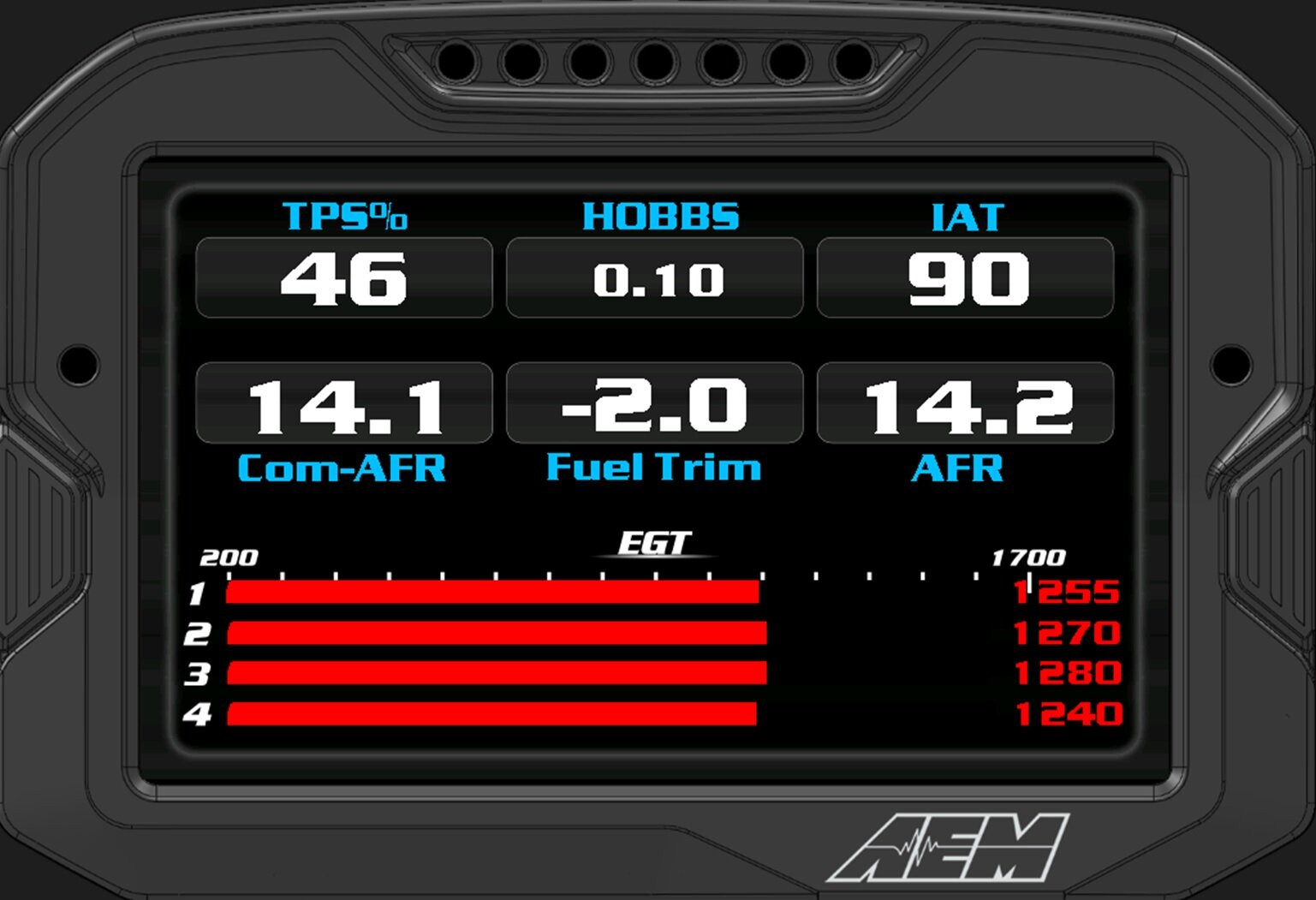

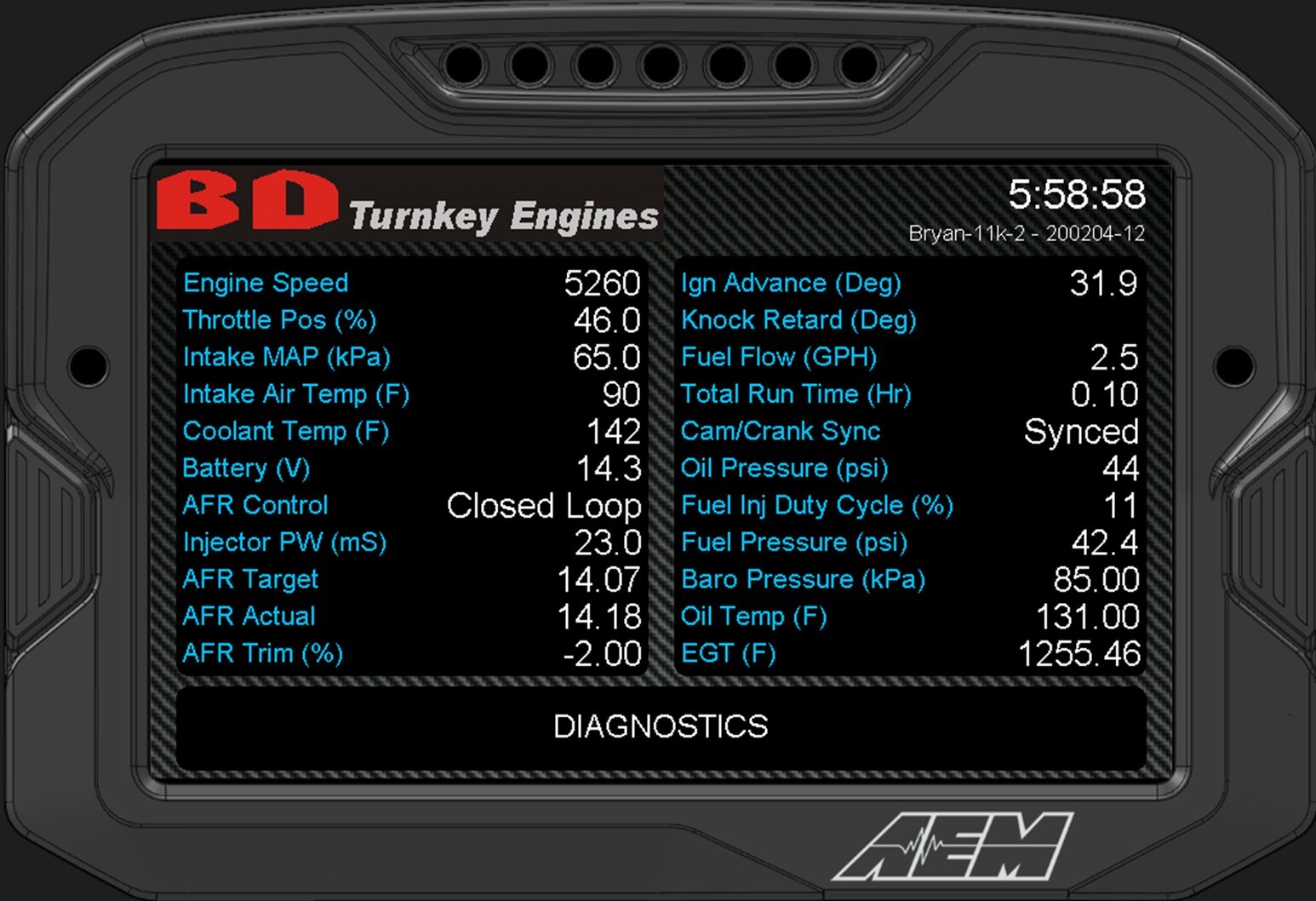

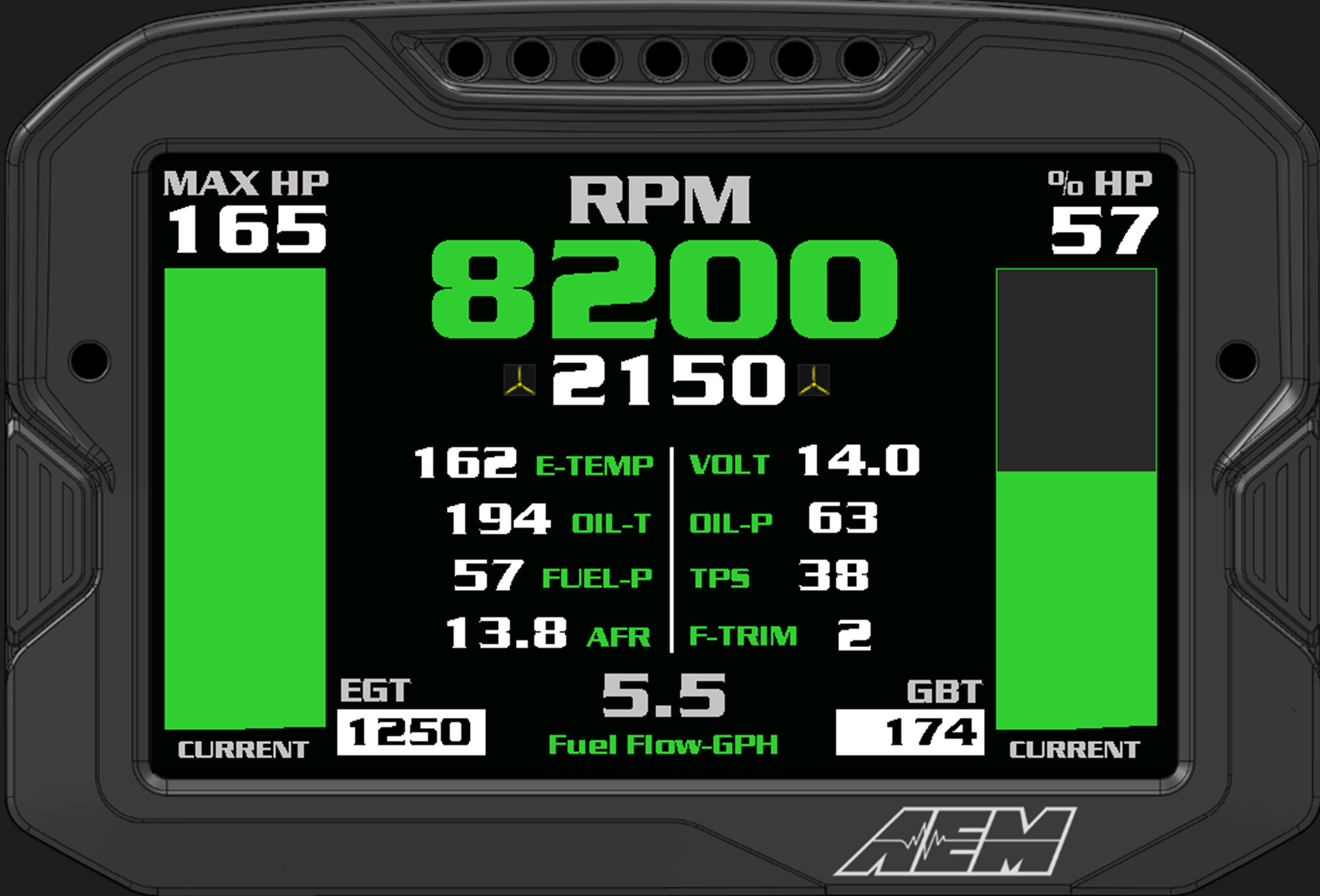

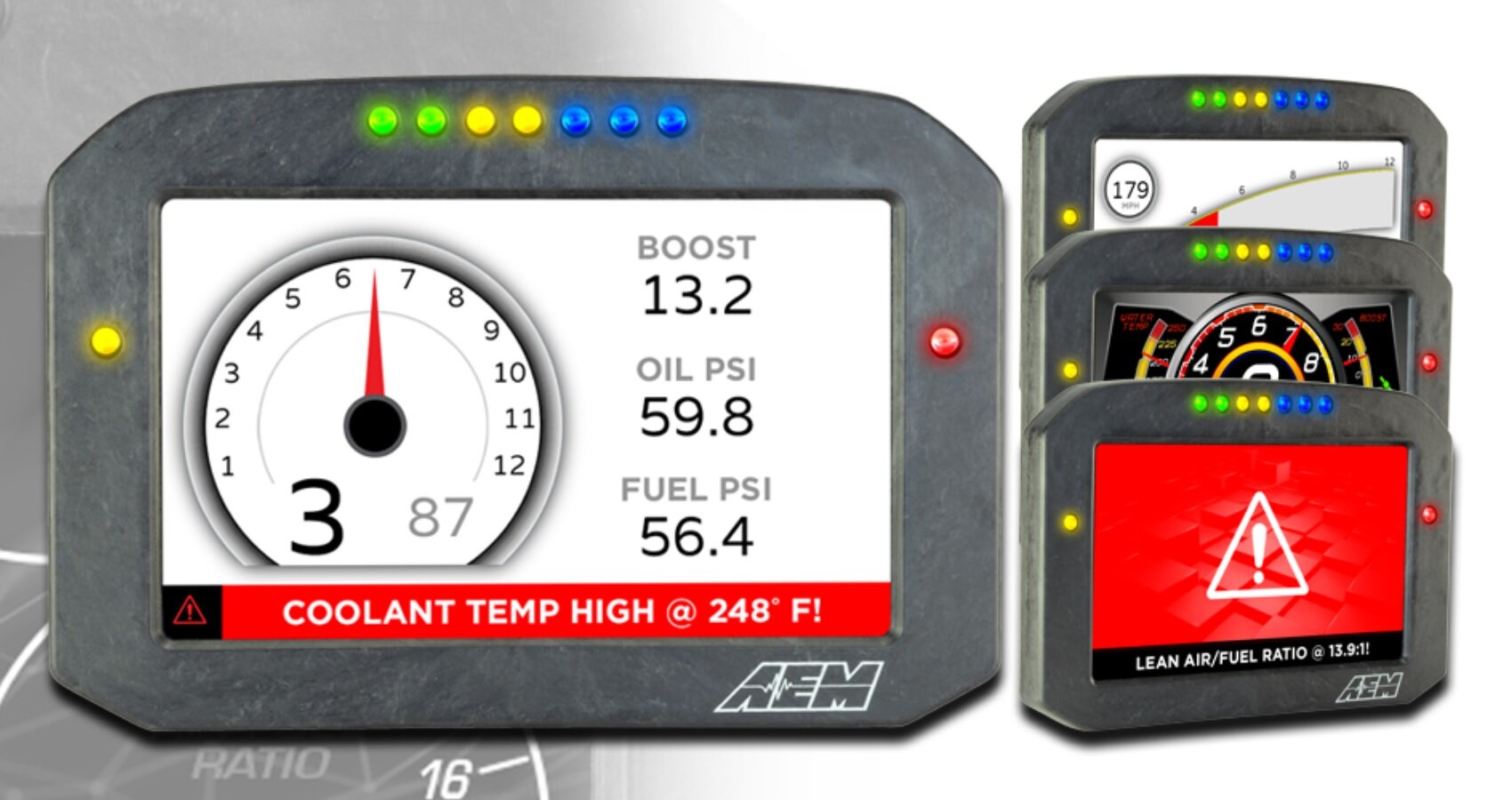

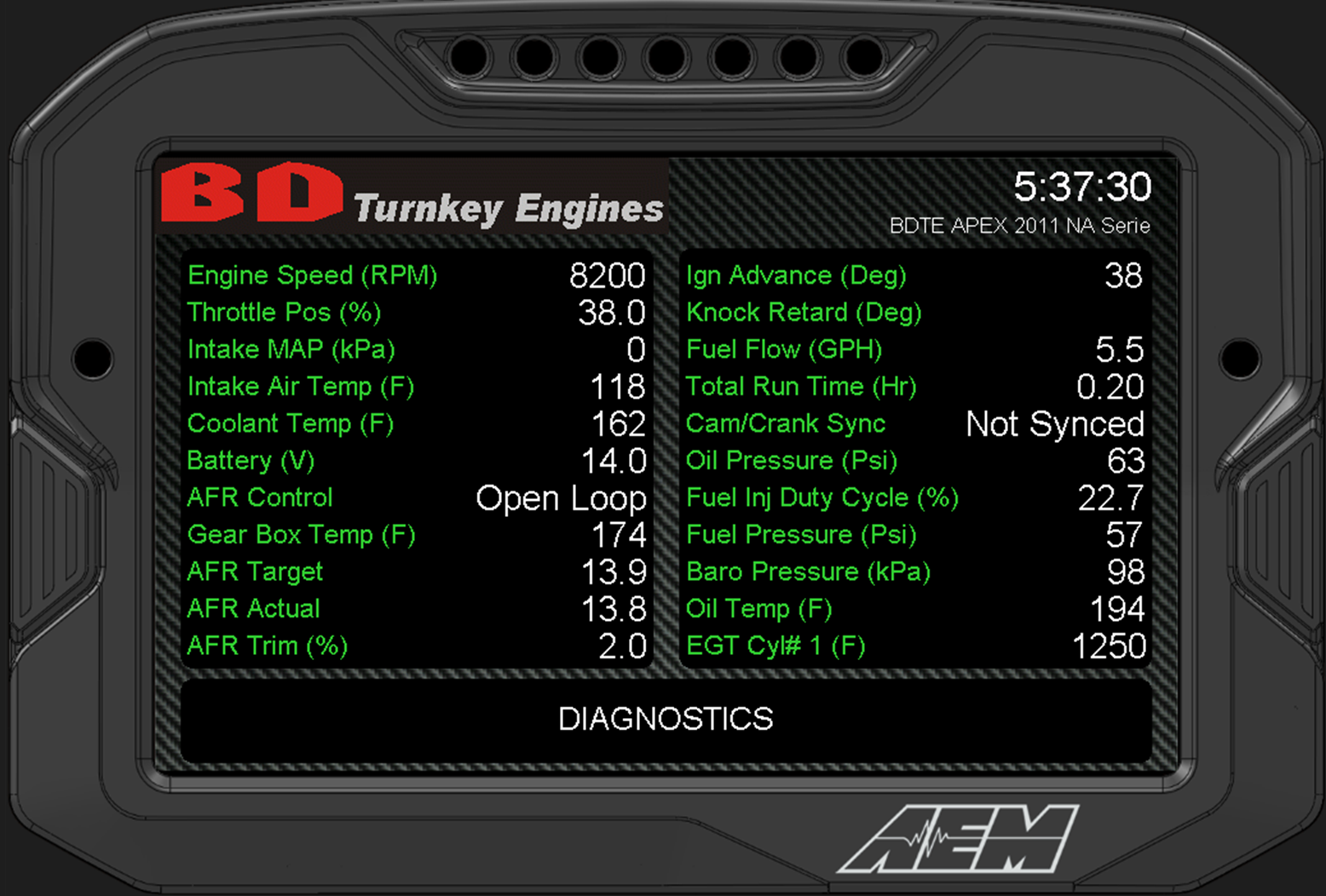

These options are for when adding Engine Monitoring via AEM’s Digital Dash - “EMS”. Each dash comes pre loaded with a specifically configured layout for Aviation and associated common sensors as seen in pictures below.

5in Digital Dash, Surface Mount, 30-5600 - $1300.00

7in Digital Dash, Surface Mount, 30-5700 - $1700.00

Oil Temp Sensor, w/ metric adapter 30-2013 - $95.00

Gear Box Temp Sensor, extended, 30-2013 - $125.00

Oil Pressure Sensor, w/ adapter 30-2130-100 - $180.00

Fuel Pressure Sensor, w/ fuel rail adapter 30-2130-100 - $230.00

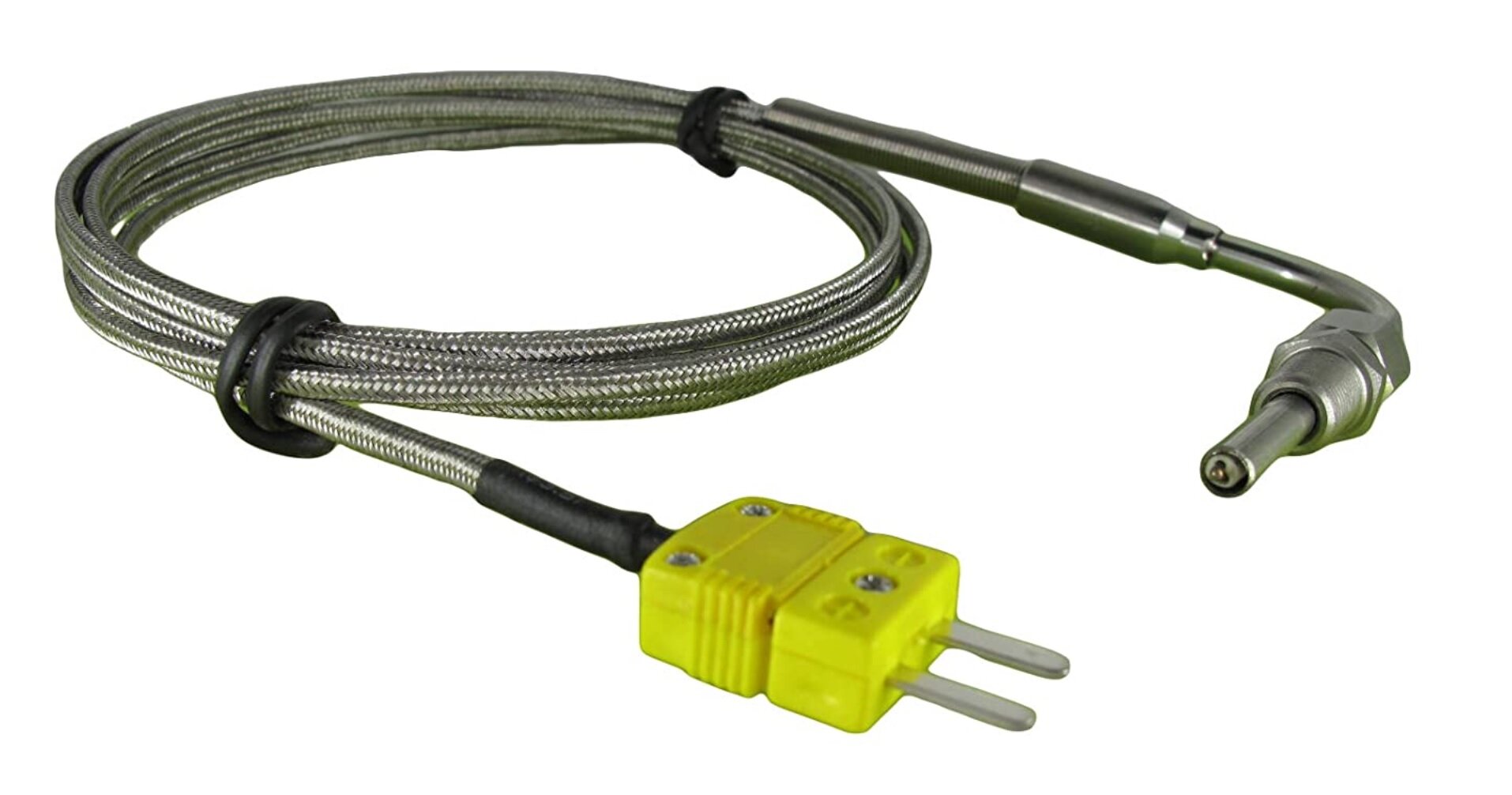

EGT CAN Module, 4 Sensors & Bungs - $670.00

The CUSTOM BD Digital Dash “EMS” displays the following information:

Engine RPM

Prop RPM

Engine Oil Temp

Engine Oil Pressure

AFR, air fuel ratio via wideband O2 sensor

AFR - Commanded/Requested

Fuel Trim, +/- fuel adjustments from base fuel map

Fuel Pressure

Fuel Flow in Gallons per Hour

Available Max HP, corrected for altitude

Current % HP

Engine Coolant Temp

TPS, throttle position %

Volts

EGT, Exhaust Gas Temperature

Gearbox Temp

IAT, inlet air temperature

HOBBS, total engine run time

Intake MAP, manifold pressure

Barometric Pressure

Injector Pulse Width

Injector Duty Cycle

Ignition Timing

Knock Timing Correction

Safety / Warning Features Include: Low Oil Temp, Low Oil Pressure, Under/Over Coolant Temperature, Low Fuel Pressure

DASH / EMS DEMO of Warnings & Critical Warnings

General Layout and Functionality

MAIN SCREEN - 0:0 min

EGT - 2:43 min

Startup - 4:47 min

Engine Coolant Temp & Engine Oil Temp - 6:25 min

Volts - 8:25 min

Oil Pressure - 10:03 min

Fuel Pressure - 12:20 min

AFR - 13:25 min

Gearbox Temp - 15:25 min

Screen 2 - 16:17 min

Diagnostic Screen - 17:38 min

Low Fuel - 18:29 min

The AEM Series 3 ECM has the following capabilities:

Airflow model based calculations

VE-based engine startup

Multi-fuel capable

Flex fuel compensated – fuel, ignition and boost with blend

Multiple boost control strategies (time, gear, vehicle speed, switch and more)

2-step programmable launch control (3-step with Advanced Tuning Package)

Programmable traction control, 2-wheel speed

No-lift shift

User configurable soft-cut rev limiters

User configurable anti-lag

Map switching (4 Separate ignition maps, 4 separate Lambda target maps, 2 separate VE tables)

Single stage wet or dry nitrous control

Integrated engine protection strategies

Target Lambda table, 10x10

Open-loop fuel pressure compensation

O2 lean-out protection

2-channel adaptive knock control

Configurable coil dwell (RPM, voltage and load based)

Individual cylinder ignition trim (RPM based)

Individual cylinder fuel trim (RPM based)

3D ignition trim maps (coolant and air temp)

Real-time sensor diagnostics

Ignition table, 20x20

VE airflow table, map vs. engine speed, 20x20

User adjustable charge temperature blend (CLT/AIT, engine speed dependent)

Idle control (stepper and pulsewidth)

Note: The following factory Yamaha components are supplied by customer and used with this system - Engine, Throttle Bodies, Starter, Fuel Rail, Fuel Pump, TPS, Mag Sensor, Cam Sensor, Injectors, Coil Packs, MAP Sensor, BARO Sensor, Voltage Regulator, etc. The following tables will be password protected for proprietary reasons: Main VE Fuel Table, Main Spark Table, and Knock Sensor Calibration Tables. Wiring harness length is typical for ECM to be mounted on the cabin side of firewall for aircraft like the Kitfox 4,5,6, & 7, Highlander, Rans, Avid, etc. All wires are terminated to associated plugs, labeled, & is plug-n-play with our Digital Dash-EMS. The series 3 ECM has many capabilities as listed below but not all are used (wired) in this Naturally Aspirated Stock configuration. It is “boost” ready & “nitrous” ready. You can utilize those features but it is up to you to wire AND tune for them. I will not support custom power adder applications. Harness is NOT wrapped! All harness & systems are built to order with a 3-4 week lead time.

Video Demo taken at 5040’ Elevation (136 Max HP) after normal engine running and shut down.

REMOTE TUNING

With this system I’m offering an initial remote tune adjustment after engine / project is complete and up and running. Best performed on the ground, “run up” style or tied down. I will supply emailed data logging layout and channel configuration but it is customer responsibility to supply a Windows based laptop, know how to use, data log session, AND email me results - Directions included with Install Manual. I will make any adjustments I feel necessary and can reflash ECM via a remote connection (Team Viewer) or you can mail ECM back. Additional remote tune sessions will be billed at $150/each.